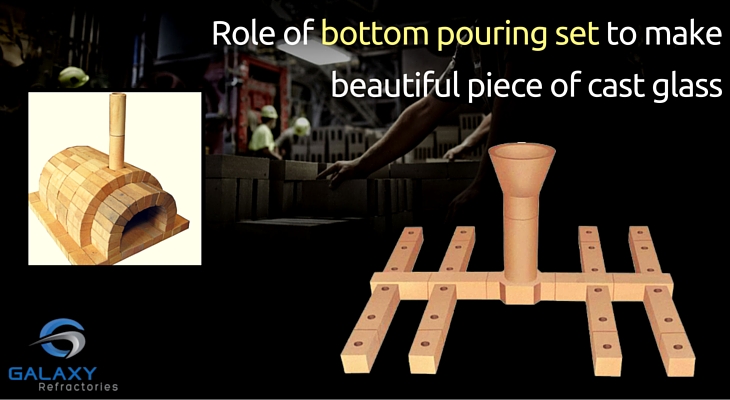

How would you possibly like to access a clear and quality ceramic kitchen appliance with no controller to form the foremost good quality bits of forged glass? Well that's the issue that Bottom pouring set is likewise suggested to as a relevant spill, the important thing is to put scrap glass into an earth box and take your oven up to 1700f temperature, at which period the currently liquid glass can spray out the openings within the lowest a part of the jar, assuredly creating advanced outlines.

This is very simple to try to everything you would like are one thing to carry enclosing like terra-cotta pot, one thing to urge the glass and pot helps. The bottom pouring set we tend to utilize $1-$4 unglazed terra-cotta pots from Lows. We do not wash them to furnace. We make in it extra gaps in the larger ones.

Decide to buy "Bottom pouring set" pots as they're more extensive at the bottom which is best and trust for everyone. Make drilling at larger openings within the lowest position of the bottom pouring set to inspire the glass to stream out all the a lot of simply. In the 6" and 8" pots drill have completely different openings, maybe 6 to 8 as this can make additionally fascinating outlines. Make certain to use craftsmanship boring equipments. They will not break the pot, which are in low cost and will make it keep going forever.

The Oven Wash

I used Bulls eye to mixing with 1.5:1 ratio with water. Actually I do know this is often thick but it secures the rack at this warmth.

The Catchers

These are optional as you'll let the glass merely fall on the chamber rack. First you need to confirm to use loads of extra thick kitchen equipments. On the off chance that you simply are thus intelligent there's no choice let the glass fall onto the kitchen equipments rather than to use ceramic products some of sizes up to interact the glass. You will also use metal loops/edges to indicate the glass thus it does not detached too so much.

The Pot Holders

You need to do one thing to freeze the bottom pouring set of the chamber rack. I put some kitchen equipments on its aspect and therefore the lay long chamber indicate crosswise over on suspend the bottom pouring set. Actually I like to suggest some recent kitchen products expire and cut 1/2" wide strips around 20" long. They are less costly that long furnace posts and aren't as high.

The Simple method

- Place bunches of chamber wash on your rack. It does not have to be compelled to dry the gap because the running kitchen appliance can traumatize that found out your chamber block and presents on suspend the bottom pouring set.

- Fill up your pot with glass. Create a perfect note of the number of quantity. Associate in Nursing far more than and it'll flood thus take care. Place bottom pouring set in pedigree - perfectly!

- Flip kitchen equipments on high level and let it last approx 3 hours but check the heating temperature. Open it at highest level of around 1700 degrees to check whether or not all the glass is out. Let all the glass run out.

- Shut down kitchen equipments and blaze cool to 1100 degrees temperature. Shut the highest level and therefore the piece can strengthen because the chamber temperature notices often. In case by chance you simply get anxious, flip it on low at 960 for hour or there about.

- Make sure to let the piece cool fully.

- You can want to clean the backs of these items. I utilize sandpaper for the tiny ones and a sixty coarseness fold sanding circle on a hand-held processor for larger ones.

The fold sanding circle takes the kitchen equipments take away in 2 seconds - no jocular. To need even the fine coarseness off absorb them muriatic corrosive for 4.5 and hit them with a wire brush. Muriatic corrosive is awful thus utilize hand, mouth and eye assurance.

Galaxy Enterprise who is expert bottom pouring set manufacturers in India has Associate in nursing sudden and entropic technique for operating with glass. As he details his shaded glass, a strategy is formed wherever by novel mix yields completely different results each in completion and composition. A couple of distinctive chiselling routines primarily based upon configuration conditions. As a rule, bottom pouring set is warm to between 1700° & 2100° wherever shading is enclosed. The liquid glass is then gravity cast and controlled utilizing stainless-steel instruments. Work is then cooled and after ward warmed for reshaping and cleaning.

Copper and atomic number 13 are used because the base metals used for mounting and show on these lines creating the work flexible in size. Aluminium could be a fantastic material for bottom pouring set in India because it is flexible for shaping and welding and is likewise light in weight - an additionally to for bigger pieces.